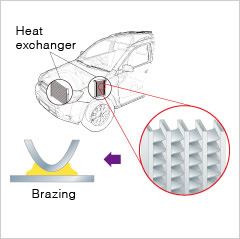

Brazing Material

Brazing technology used to join aluminum is another application of Harima’s extensive know-how. Aluminum brazing materials used in the manufacture of all kinds of aluminum products contribute to enhanced quality and reduced costs. Aluminum is commonly employed as a weight-saving measure in heat exchangers, which are an essential part of engine cooling and air conditioning in automobiles, making it necessary to braze aluminum parts of varying shapes together. Conventional manufacturing methods involved spraying the materials needed for brazing on the entire surface of heat exchanger member and then heating. However, the aluminum brazing material we engineered is an extension of our pre-coating technology and only requires that a minimum amount of brazing material be supplied just to the immediate brazing area, achieving drastic cost reductions and higher quality.

●Flux Paint for coating application ●Binder (for better adhesion of flux with aluminum tube) ●Flux paint for roll coating ●Anti-corroding clad-less brazing paint